Industrial Control

The use of electronic and electrical components, machinery, software combination to achieve the control layer, drive level execution layer requirements, so that the factory’s production and manufacturing process more automation, efficiency, precision, and have controllability and visibility.

According to customer needs, Rexel customized automation optimization and digital business for customers to save costs, improve production efficiency, and create higher value.

Motion Control

Motion control refers to the transformation of predetermined control scheme and planning instruction into desired mechanical motion under complex conditions, so as to realize precise position control, speed control, acceleration control, torque control or force control of mechanical motion.

Rexel provides multi-brand frequency converters, servo drives, etc. for a wide range of machine tools, textile machinery, rubber and plastic machinery, printing and packaging machinery, food and beverage machinery, tobacco machinery, medical equipment and research equipment industries.

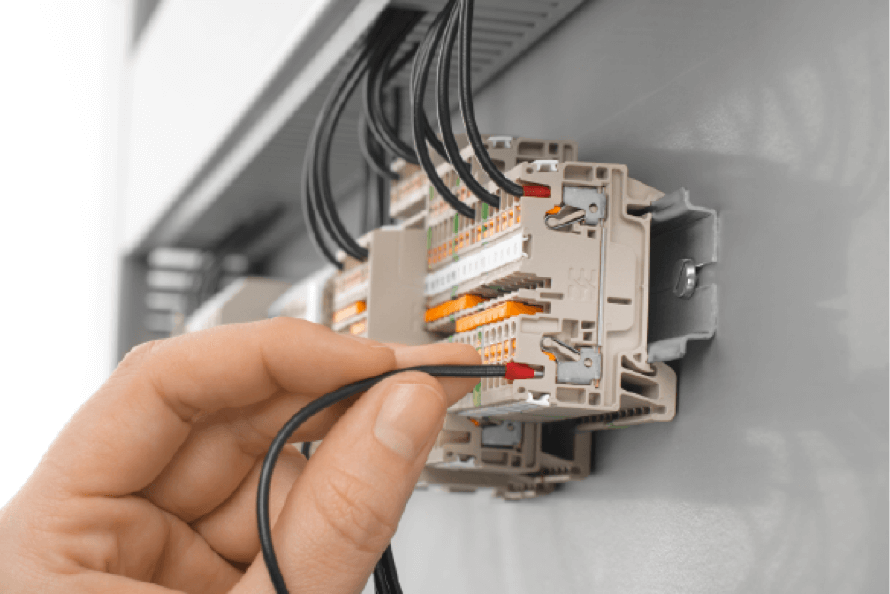

Industrial connection

Industrial connector is a coupling device that connects electrical terminals to form a circuit. Connectors are used to connect wires, cables, printed circuit boards and electronic components. Widely used in mechanical automation, control cabinet, robots, lifting, automobiles, traditional energy and new energy and other fields.

Rexel’s professional team can assist you to customize professional electrical connection products and solutions to meet your design needs, helping to improve your production efficiency.

PTD

PTD (Power Transmission and Distribution) equipment is a very important part of modern industry, which plays a vital role in the energy supply, transmission, distribution, electric energy conversion and other links.

Our professional team has rich experience in power distribution solutions and project implementation to develop customized and efficient systematic solutions for customers.

Cabinet

Based on technology of cabinets, temperature control and power distribution system depth understanding of customer needs in different industry as a starting point, Rexel’s professional technical team always committed to provide you with the most practical, high quality products, customized cabinets distribution solutions and high quality service, helping the realization of the digitized, informationalized and intelligentized production line and factory.

Instruments and Apparatus

Through various kinds of sensors, transmitters, to achieve the temperature, pressure, liquid level, capacity, force and other physical quantity measurement and display, and with a variety of actuators on electric heating equipment and electromagnetic, electric valve PID adjustment and control, alarm control, data acquisition and record.

We cooperate with famous instrument brands at domestic and abroad to provide customers with multiple process control solutions.

Industrial Cable

Cable and wire products are widely used in energy, transportation, communication, automobile and petrochemical industries. Cable and wire, also known as the blood vessels and nerves of the national economy, is related to the transmission of information and communication, the operation of industrial minerals, the operation of railway traffic and other aspects of safety, and is inseparable from people’s production and life.

Rexel selects qualified cable suppliers, to provide customers with high quality, a variety of cable products, to meet every industrial application scenario.

Lighting and Security

Rexel has been working closely with the world’s leading lighting and security suppliers to provide industrial, commercial and residential customers with the best lighting and security product portfolio and solutions, such as professional consulting, system planning, design, installation and service.

Digitalized Solutions

Rexel industry digital system architecture based on IoT, big data and cloud computing, artificial intelligence and other industrial architecture design of Internet technology, from the edge to the cloud systematic design, realizes the automation and digital integration, platform function coverage data access and margin calculation, data management, data analysis and data presentation, etc.

By deploying intelligent gateway and other Internet of Things devices on the edge, real-time data of production operation, equipment status, alarm and other real-time data of the device are collected and uploaded to the real-time data processing cluster of the industrial Internet platform. In combination with the factory parameter model, a unified production operation data platform is built.